Highly Equipped

GruppoNueva always believed in investing into the Technology. With that mindset Company is in association with the Leading Machinery Brands like Sacmi, HopeTech and Ceramic Instruments which are also the Industry Leaders in their own categories. GruppoNueva has invested heavily in Innovation with the Development of Full Body Sintered Stone Category. As a result it’s pioneer in Giving the High End Alternative of Natural Granite which can be engraved, carved, moulded and given any shape.

Because to advance you must keep evolving, we introduce the material for great ideas.

High Performance Machinery

GruppoNueva is equipped with the best technologies to produce high performance products. Gryphon Ceramics is the only company in asi having both Sacmi and System Pressing technology

SACMI is pioneer in firing and pressing equipments and all GruppoNueva factories are equipped with SACMI firing instruments

SYSTEM Ceramic is world leader in making Digital Ceramic Printing machinery, all the facilities are using System Creadigit series with latest Printing heads and advanced digital inks

To produce high quality color body slabs, GruppoNueva have ReColor system from the Italian Entrepreneur CMF Technology

All the material is moved automatically from the Press, up to the packing. All this is possible by CMF Technology

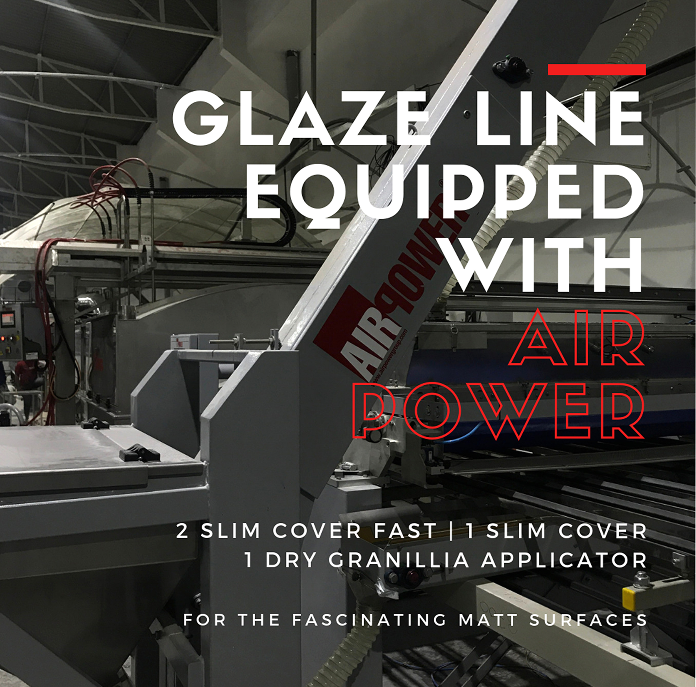

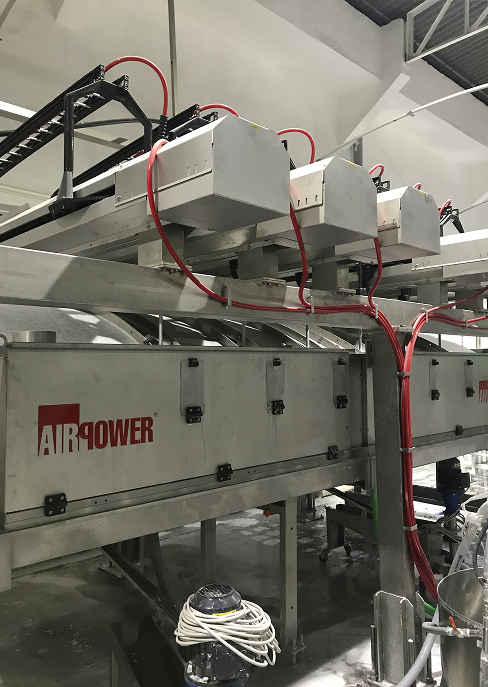

Glazing Line is the important part in development of consistent quality product with highest level of satisfaction, All facilities are equipped with the Air Power Glazing Equipments

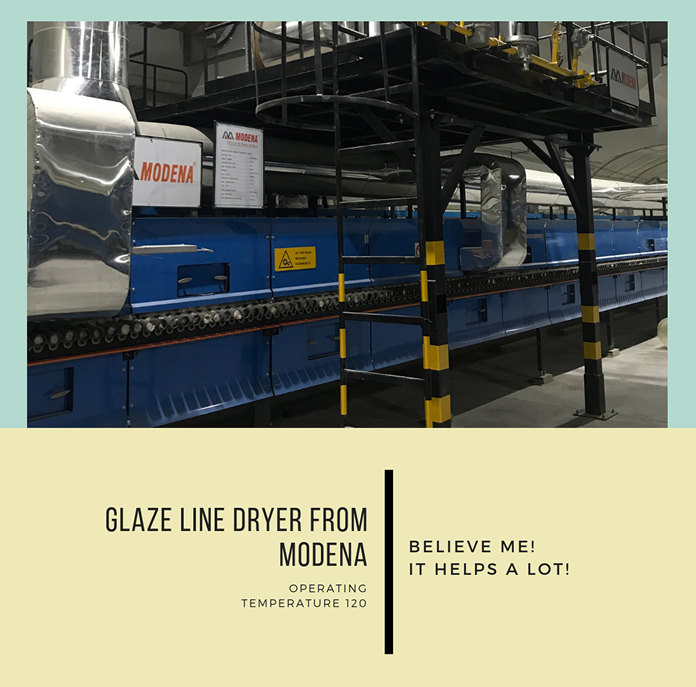

To achieve highest level of accuracy and avoid all the micro level defects, attention to details is necessary. Glaze Line dryer helps in drying the ink on the Glazing line before it goes to the final Glazing application